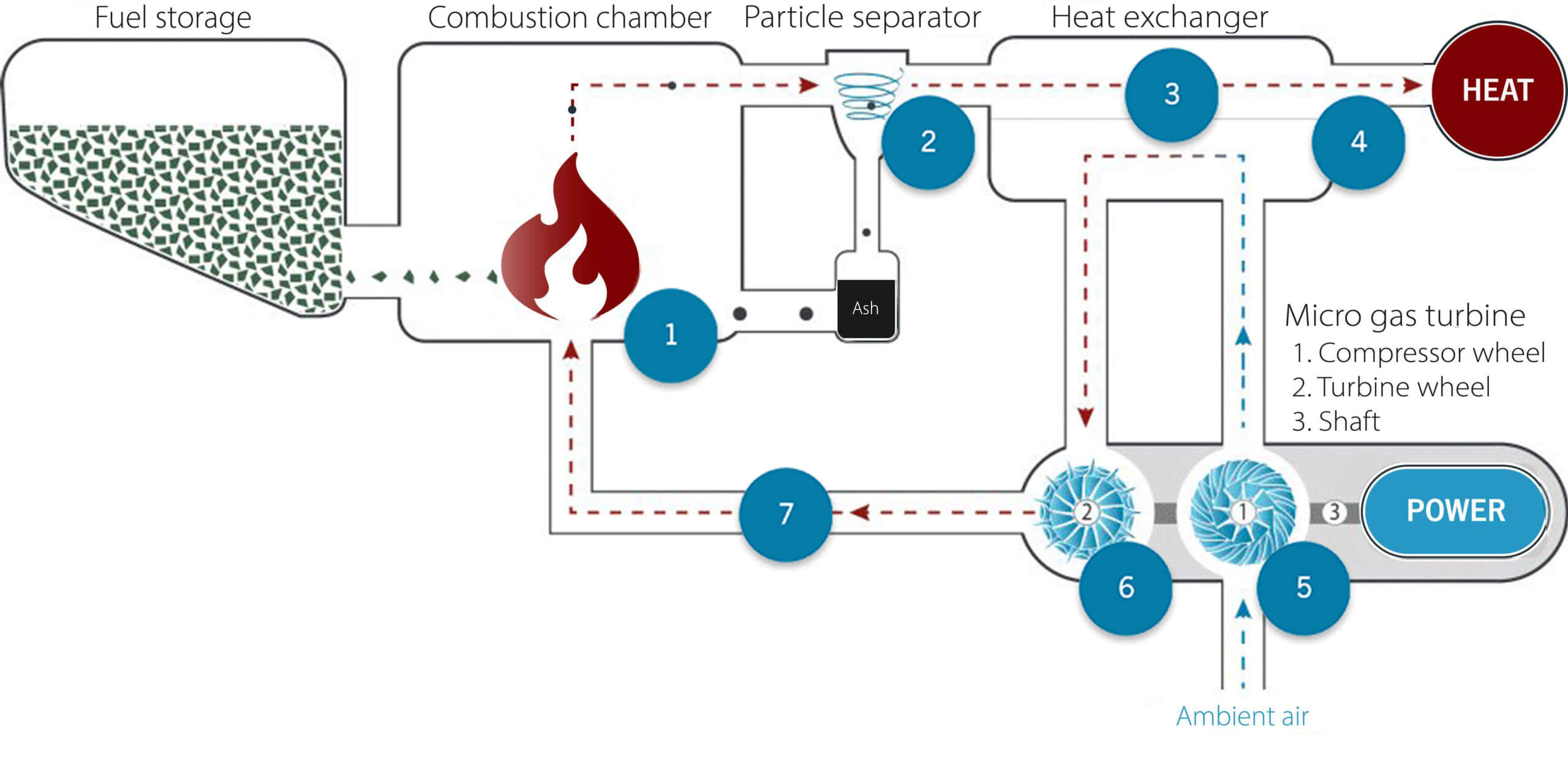

Energy generation from wood: We convert wood residues and wood waste into energy and heat by means of our innovative CHP ClinX! With the development of the externally fired micro gas turbine (EFGT), we have made it our task to efficiently use even low energy potentials and to enable an environmentally friendly utilization of residual materials.

ClinX, the CHP system, stands for “Clean Incineration of X” – the clean combustion of any residual materials or biomass. These residual materials are converted decentrally on site into electricity, heat and or cooling and made usable instead of being disposed of at a cost. For B+K, there is no waste, only energy sources. The decentralized energy supply or power generation, exactly where it is needed, makes ecological and economic sense.