GREEN ENERGY SYSTEMS COMBINED HEAT-POWER PLANT (CHP)

Individual consulting for energy generation plants & green energy systems from Germany! We see ourselves as our customer’s partner. From the first idea of decentralized energy generation or post-combustion biomass conversion, to the complete realization and acceptance of our Combined Heat-Power Plant (CHP) ClinX. In addition to our core products ClinX WOOD and ClinX HEAT we offer various other services and products. The complete service and product overview of our portfolio is presented below on this page — based on our own quality standards:

Accompanying the customer throughout the whole project — we want to remove every obstacle that is in the way of the path to project implementation.

We want to continually expand our service scope to include service trades and subsystems. For this purpose, we are establishing more cooperation and expanding our offer.

Clarity about our services — services and products can be bought only if the customer understands what we offer.

Make your choice: Our cross-industry customers can choose freely from the following modules. A subsequent (service) adjustment is of course possible at any time! Do you have any questions about our service modules? Then we look forward to hearing from you via E-Mail!

MODULE ➀: CLASSIC PRE-PROJECT PHASE

MODULE ➁: PROJECT SERVICES

MODULE ➂: OUR GREEN ENERGY SYSTEMS

MODULE ➃: INDIVIDUAL SUBSYSTEMS

MODULE ➀: ENERGY GENERATION PLANTS CONSULTATION & PRE-PROJECT PHASES

1. CLASSIC PRE-PROJECT PHASE

The integration of the plant for residual material recycling and energy production should be analyzed for technical, economic, legal and environmental suitability, depending on the selected modules. More detailed information about our Pre-Project Phase »

2. TECHNOLOGICAL ENERGY CONCEPT

Besides our CHP ClinX WOOD/HEAT systems, other complimentary technologies are included in the project evaluation. More information and details about the Technological Energy Concept »

3. TECHNOLOGICAL EXAMINATION OF UNCONVENTIONAL FUELS

Individual preliminary evaluation of the suitability of the EFGT (with heat generation from pyrolysis/combustion etc.) can be performed for a specific fuel.

4. ACCOMPANYING ENGINEERS

We assist customers in energy and technical consultation. Individual offers are prepared and fees are based according to the actual amount of work involved.

5. INCENTIVE PROGRAMS

We analyze which funding program is best suited for your application. Thus, the boundary conditions play a decisive role.

6. FUNDS SUPPORT

We analyze which funding program is best suited for the application at hand. Thereby the boundary conditions play a decisive role.

MODULE ➁: OUR PROJECT SERVICES

#GREENENERGY

TOGETHER FOR THE ENERGY TRANSITION

We have made it our mission to enable the environment neutral utilization of existing energy reserves and thus contribute to the success of the energy transition.

» APPROVAL SUPPORT:

We support the client during the approval phase.

» ACCOMPANYING ENGINEERS:

We accompany the customer individually during the realization.

MODULE ➂: GREEN ENERGY SYSTEMS | COMBINED HEAT-POWER PLANT (CHP) ClinX

We know that residual waste materials should be used much more efficiently. With innovative ideas, we are working for a clean future. Our approach: the Combined Heat-Power Plant (CHP) ClinX: The decentralized energy supply of electricity and heat from biomass! The different process technologies of ClinX WOOD or ClinX HEAT are described below:

ENERGY SYSTEM CLINX WOOD

ENERGY SYSTEM CLINX HEAT

ClinX WOOD. ClinX WOOD. The innovative Combined Heat-Power Plant (CHP) for the conversion of wood residues! ClinX WOOD is designed for heterogeneous, woody residues and fuels. The special feature of ClinX® is that even wood residues with a high proportion of branches and bark and a high water content can be converted into electricity and heat in the decentralized power range of < 1 MWel. All information related to energy from wood residues can be found HERE.

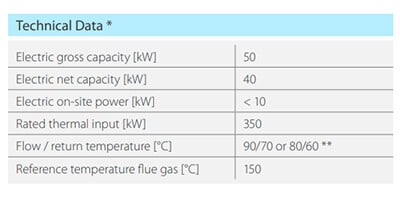

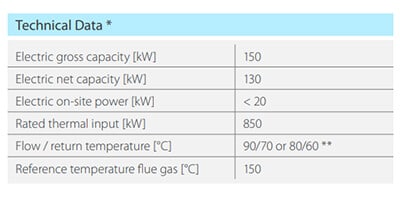

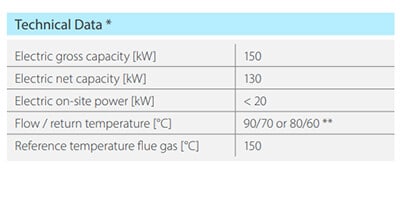

» Power classes and technical data: ClinX WOOD 50 as well as ClinX WOOD 150

ClinX HEAT is a compact, container-based system with prefabricated connections for an easy system installation. Exhaust heat is directed into a unique high-temperature heat exchanger. Clean, hot air is sent from the heat exchanger to the micro turbine. The hot air is sent through the turbine blades, which cause it to rotate and eventually drive the compressor and generator. The turbine exhaust air is recirculated as hot combustion air, which saves fuel and thus money.

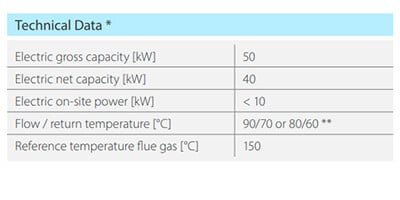

» Power classes and technical data: ClinX HEAT 50 as well as ClinX HEAT 150

What distinguishes the ClinX process (CHP ClinX WOOD) from a conventional turbine process?

The fundamental difference is the spatial separation of combustion and an external energy supply in the gas turbine by designing for the combustion process to occur in a separate chamber. This allows for an aerodynamic decoupling that results in a more complete combustion of solid fuels.

What are the main modules of our CHP ClinX WOOD unit?

Our CHP ClinX WOOD consists of the following components: Fuel Storage, Oven + Particle Separator, High Temperature Heat Exchanger, Economizer, Flue Gas Cleaner, Micro Gas Turbine, and Generator. You can also find more detailed information on the Section Page.

How is the heat extracted by the CHP ClinX HEAT unit for our customer?

The heat is extracted via the economizer (in the high-temperature exchanger) by recovering residual heat from the exhaust gas.

Potential heat utilization/applications for the CHP ClinX HEAT:

- Heating or process heat

- District heating networks

- Drying heat for upstream or downstream (production) processes

- Refrigeration machines

MODULE ➃: INDIVIDUAL SUBSYSTEMS

The entire portfolio includes advanced technologies and services guided by the principle of sustainability. In addition to the portfolio cited earlier in this document we offer our customers the following CHP products to integrate into their projects:

Sliding floor container 36 m³

Sliding floor dryer

Refrigeration module

Peak load boiler

Electricity storage

Heat storage